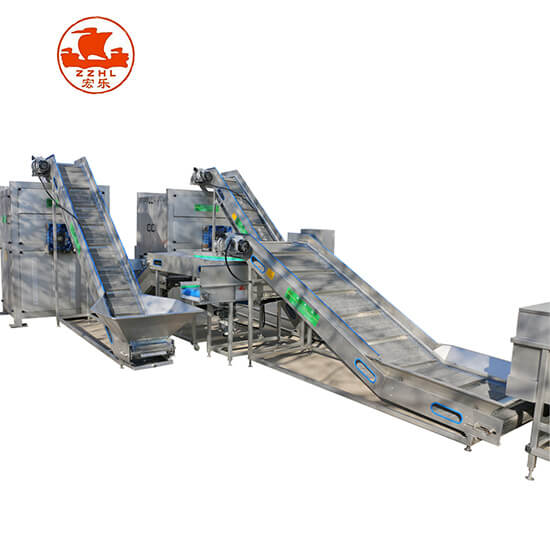

The automatic puffing production line for fruit and vegetable chips is independently developed, with independent intellectual property rights and international leading technology processing equipment. The fruit and vegetable processing has achieved a leap from frying to non-fried. The fruit and vegetable pressure difference puffing drying technology adopted is a new, environmentally friendly and energy-saving non-fried puffing drying technology. The basic principle is to combine pretreated fruit or vegetable raw materials. The temperature is increased and pressurized in the puffing tank, and the pressure is released instantaneously after a period of time. The moisture inside the material is instantly vaporized, evaporated and expanded, and dehydrated and dried under vacuum, thereby achieving the effect of volumetric serving and crisp taste. Note: Can be customized according to customer production requirements.

Variable pressure puffing, as the name suggests, is based on the principle of "popcorn". During puffing, the pretreated fruit and vegetable raw materials are put into a pressure tank, and the water in the fruits and vegetables is continuously evaporated by steam heating, and finally the internal and external temperatures of the fruits and vegetables become consistent. At the same time, water vapor is generated to make the pressure in the tank continue to rise, and a pressure value is set to reach a certain pressure, and the pressure is reduced instantaneously, so that the moisture inside the material suddenly vaporizes and flashes, and a strong vapor pressure difference is generated inside the fruits and vegetables. Cells and tissues expand to achieve the purpose of expansion.

Finally, it is dried under vacuum and low temperature to less than 5%. After cooling, the whole fruit and vegetable chips are taken out. This equipment can maintain the nutrients and fresh flavors of fruits and vegetables, thoroughly dehydration, crispy taste, full shape and uniform puffing.

Equipped with appropriate production technology. It can process a variety of fruits and vegetables, such as mulberries and bayberry. Raspberry, blueberry, chickpeas, golden pear, mango, grass fruit, jujube, kiwi, dragon fruit, cantaloupe, wolfberry, pineapple, banana, kelp, strawberry, carrot. Mushrooms, garlic, etc.

Features :

During the processing, the original nutrients, trace elements and minerals of fruits and vegetables are retained to a large extent. During the production process, there is no noise, no pollution, low energy consumption, and meets environmental protection requirements and food hygiene standards. Stable performance, simple operation, convenient maintenance, safe and efficient.

-

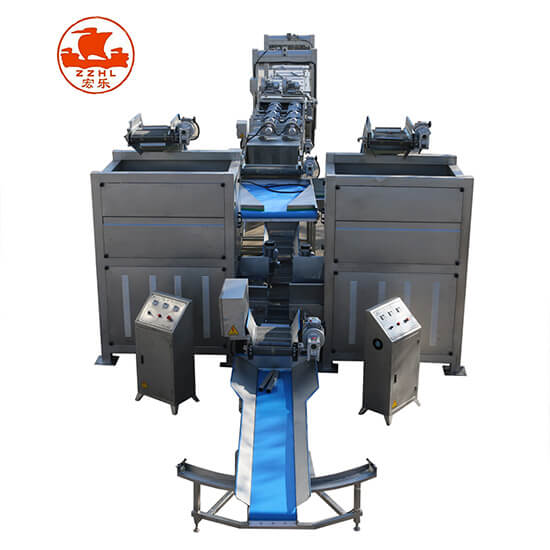

The machine consists of stainless steel and alloy. Imported cutting tools, Taiwanese motor, alloy hopper, wire tray, disc and disc form the rhizome cutting part.

The machine consists of stainless steel and alloy. Imported cutting tools, Taiwanese motor, alloy hopper, wire tray, disc and disc form the rhizome cutting part.

High Speed Dicing Machine

-

Digital cutting machine is a new type chopping machine used in the latest digital technology development. This machine is mainly used for cutting all kinds of stems and leafy soft vegetables, and slicing vegetables or slender vegetables.

Digital cutting machine is a new type chopping machine used in the latest digital technology development. This machine is mainly used for cutting all kinds of stems and leafy soft vegetables, and slicing vegetables or slender vegetables.

HL-680 Vegetable Cutting Machine

-

With different blade set, they can be cut into slice, shred, thread or cubes. It’s suitable for small-scale restaurants, canteens, school and factory dining hall and so on.

With different blade set, they can be cut into slice, shred, thread or cubes. It’s suitable for small-scale restaurants, canteens, school and factory dining hall and so on.

Electric Industrial Vegetable Cutter Slicer

-

Root vegetables, potatoes, sweet potatoes, potato head, melon, bamboo shoots, onions, eggplant; leafy vegetables: celery, cabbage, spinach, Korea dishes of dice, long strip sheet, strips, the cutter can be simple to change, to meet the different needs of production.

Root vegetables, potatoes, sweet potatoes, potato head, melon, bamboo shoots, onions, eggplant; leafy vegetables: celery, cabbage, spinach, Korea dishes of dice, long strip sheet, strips, the cutter can be simple to change, to meet the different needs of production.

HL-681 Electric Industrial Vegetable Cutter

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.