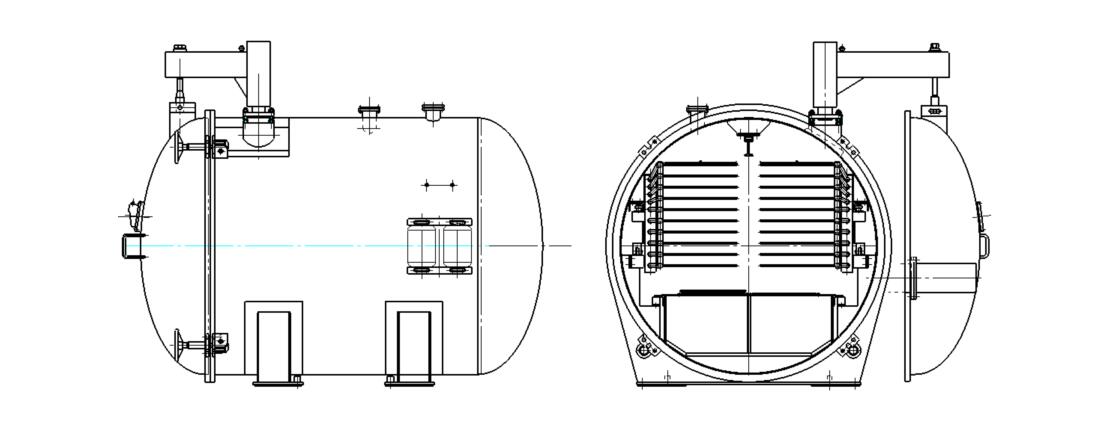

Drying chamber

Drying chamber is a horizontal tank that is made of stainless steel 304, Shell thickness is 8 mm, Door thickness is 10 mm, Inner diameter is 2.5m, Single compartment light weight about 15 tons.

There is a sight glass on the door, and Cold trap locates under the heating plates inside of chamber, the material of heating plates are aluminum with special processing treated, High technical design and build to keep about 100% heat focus on the product during drying.

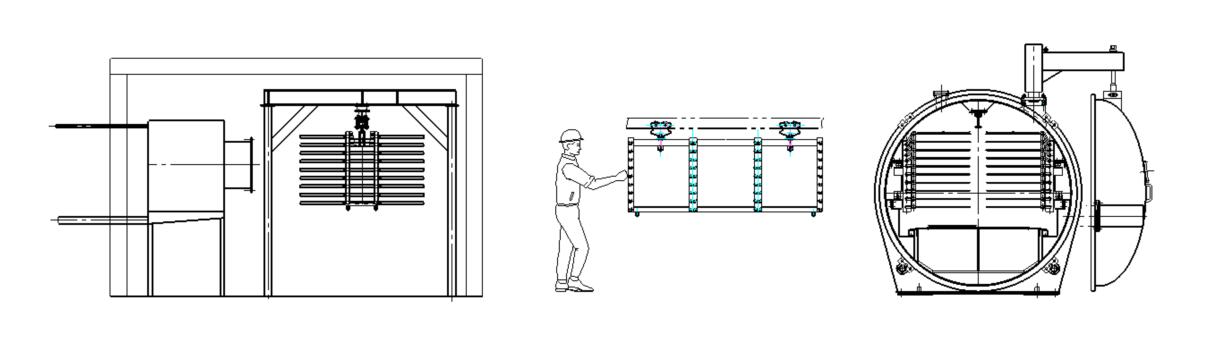

There are two stacks of horizontal heating plates in the cabinet. Each stack consists of 16 plates, cantilevered from each side of the cabinet, it can hold 300 trays per batch, and at least 5.0~6.0kg product could be put per tray, so total product capacity for raw material is 1200-1500kgfor per batch.

The material to be dried is placed in trays that are carried by trolleys in such a way that they do not come into direct contact with the heating plates.

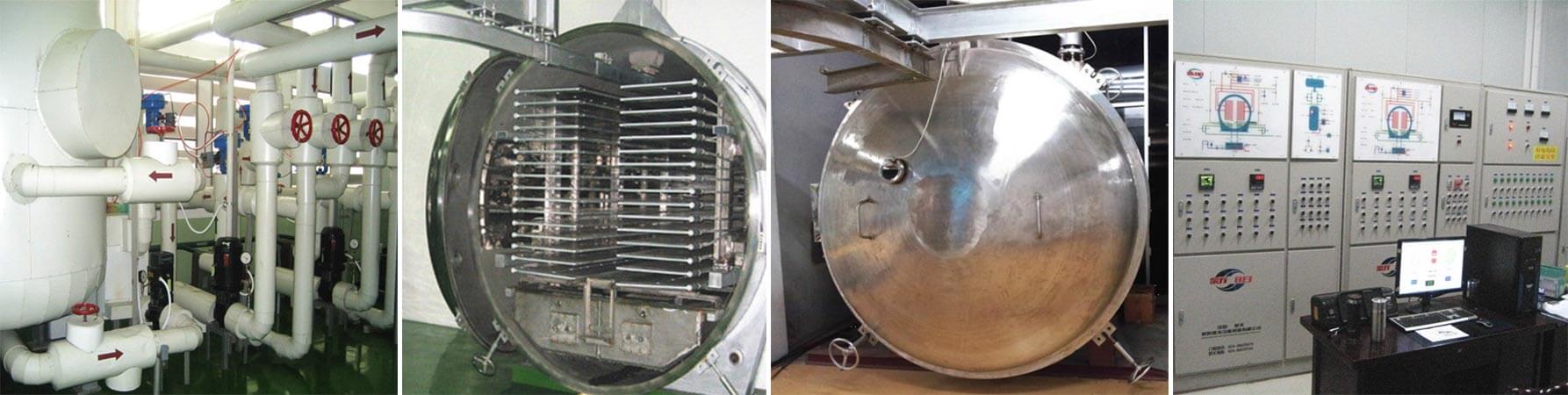

Hot water system

Hot water system is consist of hot water tank with electric heaters, heating plates,hot water circulation pump, three-port control valve and accessory equipment. High speed water is circulated by water circulation pump in hot water system, three-port control valve controlled by industrial computer to trace the setting point of water temperature that pre-set in curve. Hot media is deionized water, there is pressure release valve to keep system safety, and low temperature alarm to reminder operators.

Vacuum system

Two rotary vacuum pump evacuate the air during freeze drying processing, basically it just needs a vacuum pump to keep vacuum pressure until the end of the drying processing after two vacuum pumps create setting vacuum pressure at the beginning. High technical and precision vacuum transmitter sends signal to computer real-time, So it tells the operator true vacuum pressure and historic data is saved in computer in time.

Refrigeration system

Refrigeration system is designed to supply refrigerant for vacuum freeze dryer and quick freezing room alternately. Usually, the compressor works for quick freezing room before starting freeze drying processing, when the product in quick freezer is frozen, then changes switch to start cold trap, quick freezing room is stopped at the same time. Refrigeration system is a whole automatic system, the refrigerant is Freon or ammonia, the type of refrigerant shall be designed according to the requirement of the customer's position.

De-icing system

The de-icing system is consist of de-icing tank, water drain pump, valves, temperature controller, temperature sensors, pressure switch, etc. De-icing occurs during freeze drying, it uses low temperature vapor to defrost ice on the coils of cold trap, the water drained by water drain pump after collecting into de-icing tank when water level reaches limit setting point. Defrost processing occurs during freeze drying,it need not extra time to defrost ice after drying while unloading product from drying chamber, So it is efficient and low energy consumptive.

Control system

In order to keep the whole system running stable and reliable, the control system adopts simense PLC with industrial computer to complete center control, automatic and advanced control system is pre-programming by engineers, After a long run and a large number of experiments on experience, the humanized programming is much easier to catch by operator in short time. Furthermore, historic curve and data that was saved by computer after recording will be referred by the customer's engineers as experiments data.

Technical specification

| Dimension (exclusive freezing room) | 8.3*2.95*3.12m |

| Heating plates area | 125m2 |

| Dimension and quantity of tray | 687*568*35mm/300pcs |

| The temperature range of heating plates | Real Temp. ~120℃ |

| Condensation capacity of cold trap | 275kg/hr |

| Working vacuum pressure | 50~133Pa |

| Ultimate vacuum pressure | 20Pa |

| Refrigeration temperature | -40℃ |

| Refrigeration capacity | 200kw |

| Installed power | 85kw |

| Steam capacity | (max. as 0.7Mpa) 400kg/h |

Picture of Freeze dryer as bellow :

Introduction

In order to help you solve some of the problems, which arise during freeze-drying tests, we have the following short general description of the freeze-drying process.

Pre-treatment

Pre-treatment is to be understood as:

a) Preparation of the product before freezing

b) Freezing-and for some products also granulation before drying.

Different products are processed (pre-treated) differently, but generally a distinction is made between pre-treatment of liquid products and solid products.

When evaluating the mist suitable pre-treatment of a product, the following should be taken into consideration.

Freezing point, dry matter content, vapor escape, freezing speed and in this connection the size of ice crystals, sublimation conditions, the heat conductivity of the frozen product, drying speed, and the required qualities of the dried product such as colour, bulk density, taste reconstitution, and nutritive value.

As many variations in freeze-drying have to be considered, it is often difficult to obtain the required product characteristics while maintaining the most economical operating conditions.

Generally it can be said that a product may be successfully freeze-dried under various conditions. Thus it is not usually possible to an exact set of drying conditions for a particular product.

Dry Matter Content of Feed Material

The initial installation cost and the operating cost of a freeze-drying installation are relatively high compared with other traditional drying methods. Thus in freeze-drying it is particularly important that the solid concentration and drying conditions should be determined through extensive test work before an in dustrial installation is finally selected.

Freezing

In order not to spoil the appearance of the product and the structure of the cells during the evacuation period, the product is first frozen. The freezing temperature depends on the type of product, dry matter content, and freezing speed.

The best way to determine the freezing temperature is to find the maximum sublimation temperature (see under drying pressure)

Freezing Speed

High freezing speed will produce rather small ice crystals; slow freezing has the opposite effect. This means that a more or less finely structures, finished dry product can be obtained. This is a partial valid product. Slow freezing will result in a freezing concentration that will tend to lower the necessary freezing temperature.

Layer Thickness

The layer thickness in the trays is of great importance to the drying time. The drying time increases with the increase of the layer thickness, and further it is very important that there is an equal thickness of product in all the trays.

Water Vapor Escape

During drying of liquid products, which are frozen on the trays, the product may sometimes bubble. This is caused by formation of vapor, which occurs in the lower part of the product at the bottom of the tray. This bubbling can be prevented by.

1. Scraping of channels in the frozen product with 5 cm spacing to facilitate discharge of vapor.

2. Loosening and lifting the frozen sheet slightly form the bottom of the tray make room for vapor discharge.

3. Adapting the drying programmed (plate temperature) so that it results in a one-sided drying form above.

Drying

The drying conditions are usually determined by the pressure in the cabinet, the temperature of the product, the temperature of the plates.

-

This Fish killing machine is a collection to scale, open fish maw, gutted and fish cleaning function, can be processed silver carp, bream, grass carp, black carp, carp, salmon, mandarin fish, tilapia, perch, fish Palestinian wave all kinds of fish.

This Fish killing machine is a collection to scale, open fish maw, gutted and fish cleaning function, can be processed silver carp, bream, grass carp, black carp, carp, salmon, mandarin fish, tilapia, perch, fish Palestinian wave all kinds of fish.

Fish Scale And Gutting Machine

-

This machine is made of all stainless steel materials, wear-resistant and durable, meets the standard, is simple to make, easy to clean, safe and reliable, accurate operation of opening and opening, cleans the internal organs, does not break the fish gallbladder, automatically sprays water at the same time, rinses the fish belly.

This machine is made of all stainless steel materials, wear-resistant and durable, meets the standard, is simple to make, easy to clean, safe and reliable, accurate operation of opening and opening, cleans the internal organs, does not break the fish gallbladder, automatically sprays water at the same time, rinses the fish belly.

Fish Fillet Machine

-

This machine is specially used to remove the skin of various types of fish ,so that the fish can be processed into products soonly. We specially made the pressing roller to fix the material peeling. The peeling rate is high and the material is not wasted. The peeling thickness can be adjusted. It is a good helper for removing fish skin.

This machine is specially used to remove the skin of various types of fish ,so that the fish can be processed into products soonly. We specially made the pressing roller to fix the material peeling. The peeling rate is high and the material is not wasted. The peeling thickness can be adjusted. It is a good helper for removing fish skin.

Fish Skinning Machine

-

Meat mincer is an indispensable equipment in food processing. Meat mincer adopts the principle of rotating screw to push the materials in the feed box to the pre-cut hole plate, then, the material is cut up by the shearing action of the Rotary Cutter Blade and the hole edge on the hole plate cutter, and the material...

Meat mincer is an indispensable equipment in food processing. Meat mincer adopts the principle of rotating screw to push the materials in the feed box to the pre-cut hole plate, then, the material is cut up by the shearing action of the Rotary Cutter Blade and the hole edge on the hole plate cutter, and the material...

Meat Grinder Grinding Machine

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.