Briefly describe the process flow and functions of commercial water treatment equipment

1.Common water treatment equipment:

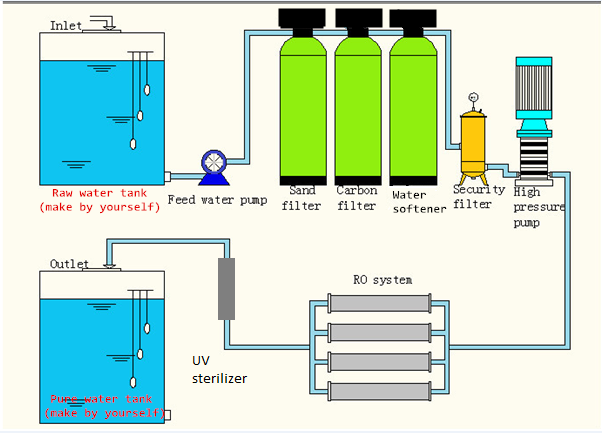

There are three common water treatment equipment: single-stage reverse osmosis, two-stage reverse osmosis and ultrafiltration equipment. Among them, single-stage reverse osmosis is the most widely used. We take single-stage reverse osmosis as an example to show you a brief understanding of the process flow of the equipment. Raw water(raw water tank)→ Raw water Pump → Quartz sand filter → activated carbon filter → watersoftener → cartridge filter → High pressure pump→ RO system → UV sterilizer→ Pure water.

Raw water tank: it plays a buffering role in the supply of raw water and coordinates the supply of raw water with the input of raw water pump

Original pump: provides sufficient pressure and water volume for the water point.

Quartz sand filter: Raw water passes through the multi-layer mechanical filtration of quartz sand filter, which can remove mud, rust, large particles and suspended matter from raw water, remove insoluble impurities in the water, colloids, free chlorine, odor, color and some iron and manganese in the water, as well as adsorb organic matter in the water, reducing the SDI value of the water.

Activated carbon filter: After the raw water is treated by the quartz sand filter, most of the visible matter has been removed, and then the activated carbon filter removes the colloids, free chlorine, odor, color and some iron and manganese in the water, as well as adsorbing organic matter in the water, which belongs to the adsorption filtration method.

(Softening Tank): To achieve higher recovery rates and prevent chemical scaling of calcium, sulfate, and Ca2+, Mg2+ ions on the concentrate side of reverse osmosis concentrate water, especially in the last membrane element of the reverse osmosis pressure vessel, which can affect the performance of the membrane elements, the softening unit thoroughly removes calcium and magnesium ion hardness from the water, protecting the reverse osmosis membrane and preventing scaling issues on the RO membrane surface, ensuring safe and stable system operation.

Security filter: The function of the security filter is to intercept particles larger than a few microns brought by raw water to prevent them from entering the reverse osmosis system. These particles may break through the reverse osmosis membrane module and cause a large amount of salt leakage when accelerated by the high-pressure pump, and at the same time scratch the impeller of the high-pressure pump.

High pressure pump: In order to overcome the osmotic pressure of RO membrane, the external pressure needs to be provided for RO membrane. This pressure is the pressure required for the normal operation of RO membrane, which is provided by high pressure pump.

Reverse osmosis membrane: Reverse osmosis is the reverse process of osmosis. In nature there is a membrane called a semipermeable membrane, which can only pass water but not other solutes. If fresh water and salt water are separated by a semipermeable membrane, the fresh water will naturally pass through the semipermeable membrane to the side of the salt water.

0.22 μm Precision Filter: The precision filter is primarily used for water purification, especially in areas with high water quality requirements. It removes fine particles from liquids to meet the needs of subsequent processes. Sometimes it is also installed at the end of a complete water treatment system to prevent fine particles and broken resin residues from entering the final product water. Deionized water is prone to secondary contamination through flow pipes and equipment, leading to increased conductivity and substandard water quality. By using a 0.2 μm precision filter, it removes any residual particles that may remain in the deionized water, ensuring the final water quality is pure.

2.Application range of different water treatment equipment

Ultrafiltration equipment:

It is often used to filter impurities in tap water, such as particulate matter, viruses, etc., to make tap water cleaner. The ultrafiltration water purifier uses an ultrafiltration membrane filter element with an accuracy of 0.01 microns, which is suitable for use in areas where water pollution is not serious.

Single stage reverse osmosis equipment:

The raw water passes through the pretreatment system and precision filter, and is sent to the reverse osmosis device through a high-pressure pump to directly produce product water, which is called single-stage reverse osmosis. The reverse osmosis water purifier uses an RO membrane filter element with an accuracy of 0.0001 microns, which can effectively filter out organic matter, inorganic matter, bacteria, viruses and other impurities in the raw water.

Two-stage reverse osmosis equipment:

The raw water (tap water, surface water, groundwater) is pressurized and sent to the pretreatment system for coarse filtration, and then enters the precision filter for filtration, and then is pressurized by the first-level high-pressure pump and sent to the first-level reverse osmosis system. The water produced by this system is then pressurized by the second-level high-pressure pump and sent to the second-level reverse osmosis system to produce finished water, which is called two-stage reverse osmosis. It is suitable for laboratory and medical water.

ZHENGZHOU HONGLE MACHINERY EQUIPMENT CO.LTD

Contact:Joe

E-mail:lucy002@hyfmachinery.com

WhatsApp: 0086-15514501051

Cell: 0086-15514501051

Website:http://chinafoodmachine.en.alibaba.com/

http://www.hlchinamachine.com

-

nodata

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.