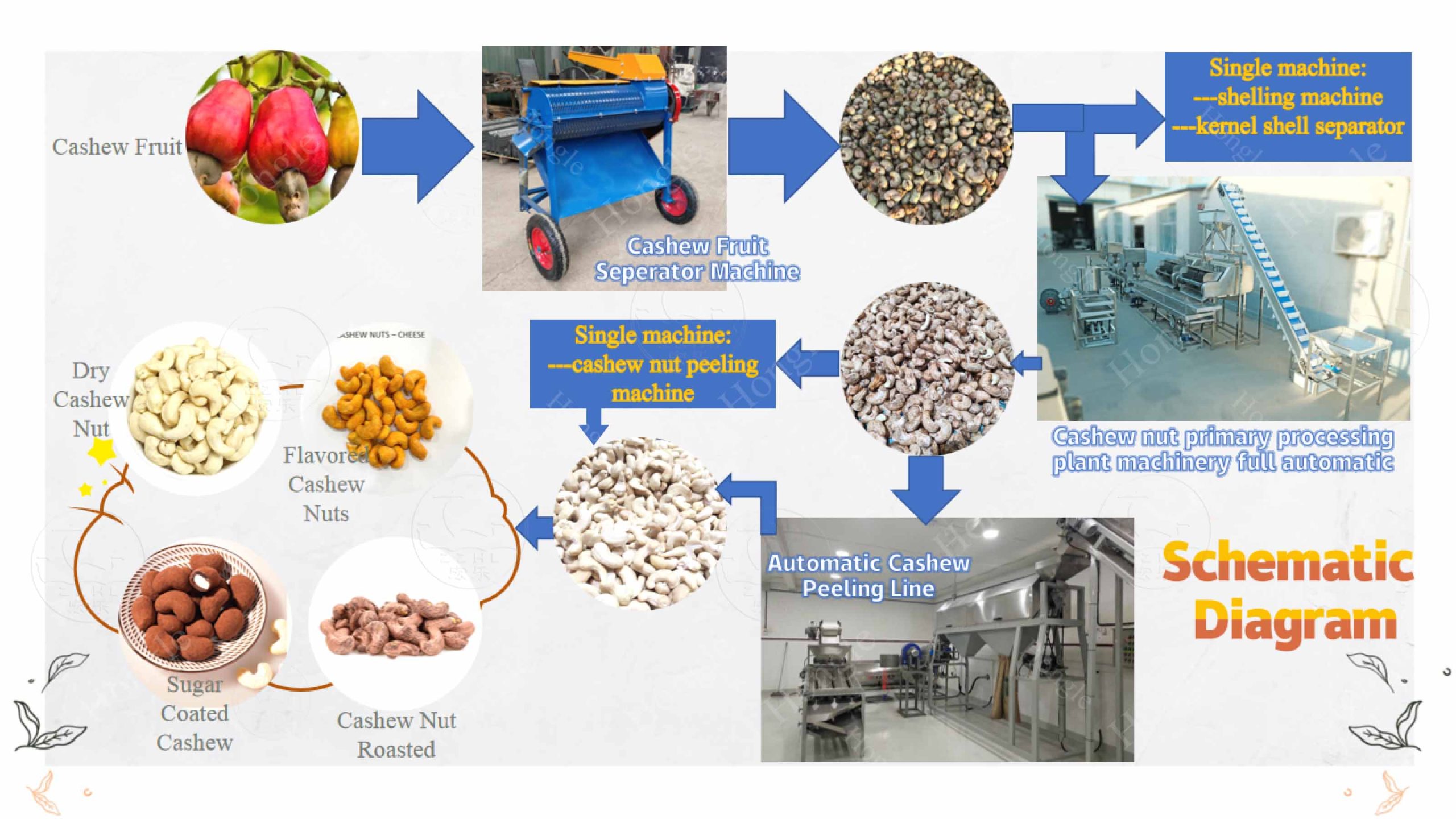

Cashew nut production line is generally divided into: grader - cooking machine - shelling machine - shell kernel separator -kernel drying - cooling (hand feel can rub the skin)- peeling machine - kernel classifier - kernel products - and then baked into various flavors and kernel products.

The cashew nut shell opening production line is a new generation of cashew nut shell opening production line independently developed on the basis of the original automatic cashew nut shell opening production line.

The production line completely solves the shortcomings of the fruit shell opening machine such as low production efficiency, low yield, poor safety, high labor intensity, and can not form large-scale production. The equipment has the advantages of large processing range, high yield and good safety.

| No | Name | Parameters |

| 1 | Raw Cashew Sorting Machine | For Grading Of Raw Cashew Nuts |

| 2 | Cashew Cooking Machine | Capacity: 300 Kg/Hour After steaming the cashews, they are easier to shell. |

| 3 | Automatic Cashew Shelling machine | Capacity: 100-150 Kg/Hour After steaming the cashews, shell the cashews. |

| 4 | Cashew Shell separator | Capacity: 500kg Cashew shell and cashew kernel separation |

| 5 | Drying Machine | (for peeling after drying Cashew Kernel) Capacity: 800 Kgs/Bacth |

| 6 | Humidifier Machine | (The drier moves directly into the humidifier) Automatic setting humidity Capacity : 800 kg/batch |

| 7 | Cashew Nut Peeling Machine | Capacity: 100 Kg/h Air Compressor Consumer: 30 Hp-20 Kw – 7 Bar |

| 8 | Air Compressor | Power 7.5kw Pressure:4--6kg Gas consumption:1 cube |

| 9 | Sorting belt | (after peeling cashew nuts) Capacity: 150-200 Kg/h |

| 10 | Grading machine | Capacity: 400Kg/h |

-

nodata

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.