High Capacity Air Bobble Conveyor Belt Mixed Vegetable Washing and Blanching Cooling Line

The blanching and cooling line is a widely used equipment in food processing, mainly used for the processing of fruits, vegetables, meat, aquatic products and other foods. The following is a detailed introduction to the blanching and cooling line:

1. Working principle

The blanching and cooling line is based on the principle of pasteurization. It uses hot water to heat the food for a short time (blanching and blanching), and then quickly cools it to kill microorganisms, enzymes, etc., to achieve the purpose of extending the shelf life of food and improving quality. During the blanching process, the machine can quickly heat up to the required temperature and keep it warm during the processing, and the heat is not easy to dissipate.

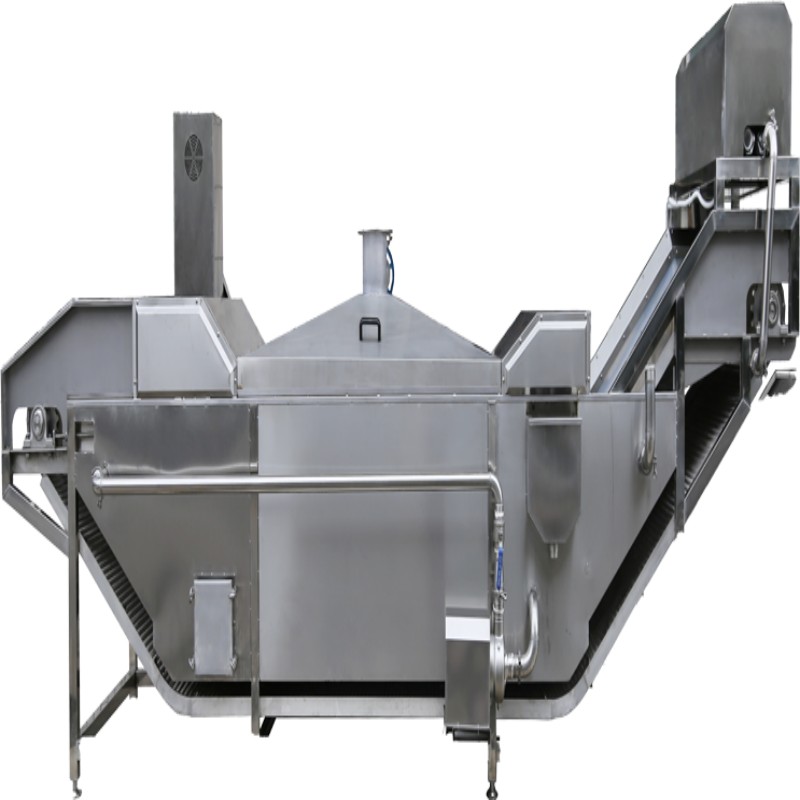

2. Main components

The blanching and cooling line generally includes blanching tank, cooling tank, conveying system, heating and cooling equipment, control system and other parts. The various parts cooperate to realize the continuous processing of food, and the processes from feeding, watering to discharging can be operated continuously without interruption. Blanching tank: used for blanching food and killing microorganisms and enzymes with hot water. Cooling tank: used to quickly cool the blanched food to prevent the food from continuing to heat and deteriorate. Conveying system: used to transport food from the blanching tank to the cooling tank, as well as the subsequent packaging or storage links. Heating and cooling equipment: used to provide hot and cold water required for blanching and cooling. Control system: used to control the operation of the entire blanching and cooling line, including the setting and monitoring of parameters such as temperature and time.

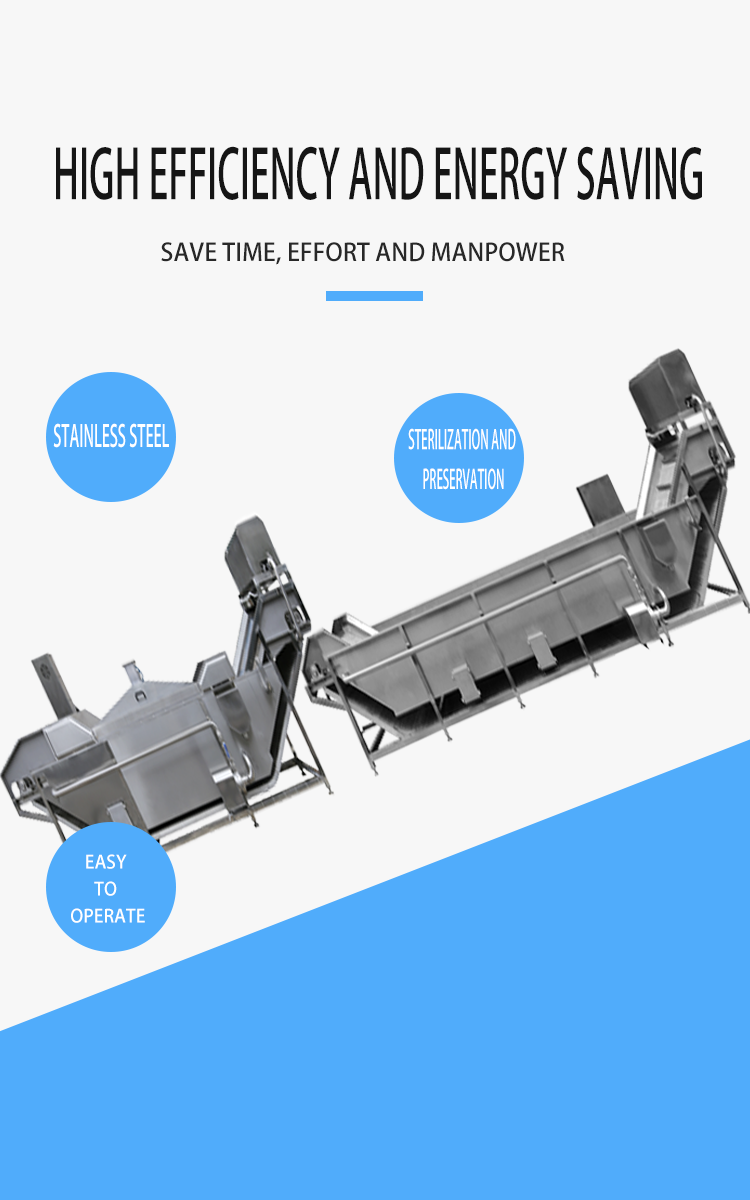

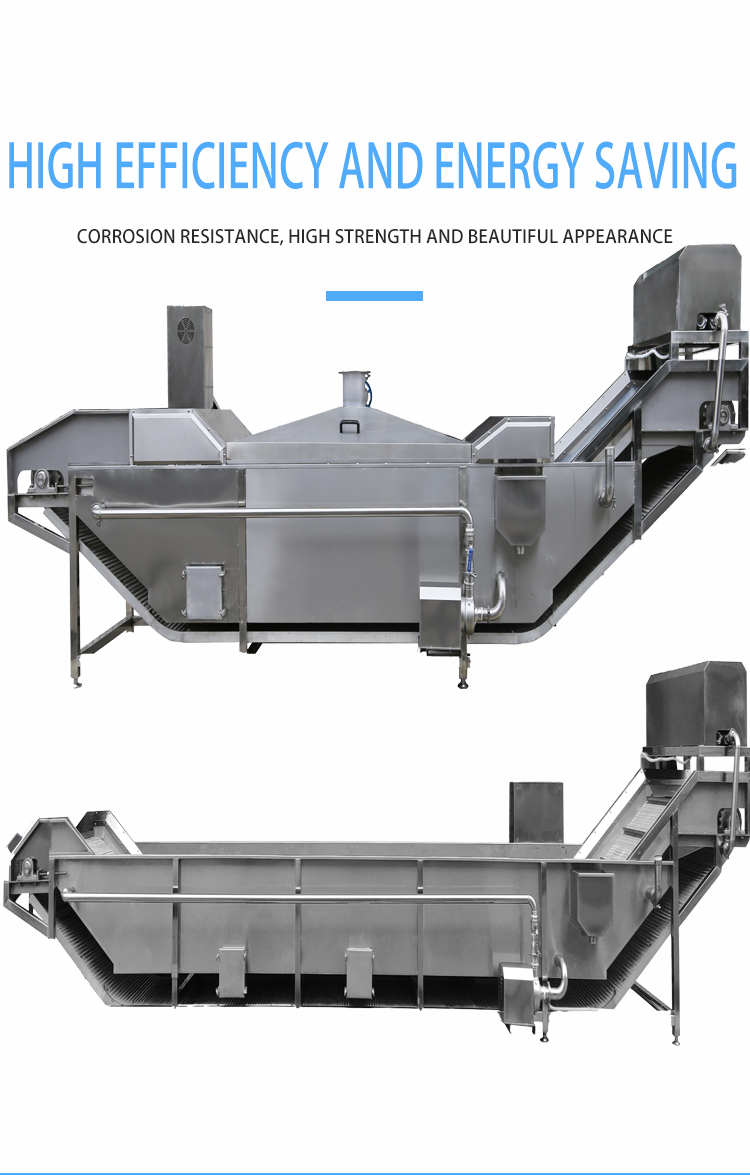

3. Features

High efficiency and energy saving: The blanching and cooling line adopts mechanized operation, which greatly improves production efficiency. At the same time, through the optimization of design and control system, the rational use and conservation of energy are achieved. Easy to operate: The blanching and cooling line has the advantages of low labor intensity and easy operation. Operators only need simple training to get started. Wide range of applications: The blanching and cooling line is suitable for the processing of various vegetables, fruits, meats, aquatic products and other foods. At the same time, it can also be customized according to the actual needs of users. Good thermal insulation performance: The blanching line is surrounded by thickened thermal insulation materials, which has good thermal insulation performance, is not easy to lose heat, and has less heat loss. Easy to maintain: The blanching and cooling line has a reasonable structural design and is easy to clean and maintain. Regularly checking the working status of the equipment's heating pipes, spray systems, and stirring devices can ensure their normal operation and extend their service life.

4. Application scenarios

Blanching and cooling lines are widely used in fruit and vegetable processing, pre-prepared food processing, and other fields. Through blanching, the activity of enzymes can be effectively inhibited, the shelf life of food can be extended, and the quality can be improved. In addition, blanching can also volatilize the green odor of vegetables, retain the original fragrance of vegetables, enhance the softness of cells, and facilitate subsequent processing and preservation.

-

nodata

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.