How to Make Tomato Paste From Fresh Tomatoes?

How to Make Tomato Paste From Fresh Tomatoes?

Ketchup is a widely used condiment that not only adds flavor to dishes, but also has rich nutritional value. The production of ketchup needs to be achieved through a series of complex process flows, involving everything from the selection of raw materials to the packaging of finished products. The following is the production process of a ketchup production line, showing every link from the processing of tomatoes to the final packaging.

1. Raw material preparation

The main raw material of ketchup is ripe tomatoes. In order to ensure the quality of ketchup, the selected tomatoes should be fresh, free of pests and diseases, and of moderate maturity. Tomatoes need to be strictly selected and washed to ensure that surface dirt and pesticide residues are removed.

Steps:

① Selection and screening: Select fully mature, bright color, high dry matter content, thin skin,thick flesh, and few seeds to ensure the quality and freshness of tomatoes to obtain good taste and flavor. This process requires manual or machine screening of tomatoes that do not meet the standards (such as overripe, damaged, etc.).

② Cleaning: Use a bubble washer or other professional cleaning equipment to rinse the tomatoes with clean water several times to remove impurities such as mud, dirt, pesticide residues, etc. on the surface.

2. Tomato grinding and concentration

The washed, peeled and seeded tomatoes will be sent to the grinding equipment for careful pulping. The purpose of pulping is to fully mix the tomato pulp and juice for subsequent processing. The ground tomato pulp will be sent to the evaporator or concentration equipment, and the water will be evaporated by heating to concentrate the tomato pulp into tomato concentrate.

Steps:

①Crushing: Use a tomato crusher to crush the tomatoes into small pieces to better separate the pulp and juice and increase the pulping rate.

②Preheating: Pour the crushed tomato pieces into the pre-heater for 2-3 minutes to soften the pulp and facilitate pulping. At the same time, it can passivate pectinase and prevent the degradation and denaturation of pectin substances to reduce the viscosity of the sauce123.

③Beating: Beat the tomato chunks into a fine pulp by a machine. Generally, a double-channel beater is used. Screens with different apertures are used. The machine can remove the peel and seeds, making the beaten juice more delicate and uniform while retaining its nutrients.

④Vacuum concentration: Put the juice obtained by the beater into a vacuum evaporation concentration device, such as a double-effect vacuum concentration device, and heat and evaporate it under a vacuum environment. Use high-temperature evaporation technology to remove excess water to concentrate the tomato pulp to the required concentration. Generally, the tomato pulp needs to be concentrated five to six times to make tomato sauce.

3. Seasoning and blending

The tomato concentrate is sent to the seasoning area, and the production staff adds sugar, salt, vinegar, spices and other ingredients according to the formula. This process is the key link in the formation of the taste of tomato sauce. Common seasonings include sugar, white vinegar, salt, onion powder, garlic powder, spice mixtures, etc. Different brands and flavors of tomato sauce will present different flavors according to different seasoning ratios.

Steps:

①Ingredients: According to the specific production formula of the product, accurately weigh the appropriate amount of sugar, salt, vinegar, spices and other seasonings.

②Mixed seasoning: Add the prepared seasoning to the concentrated ketchup, and then mix it thoroughly in a large mixing tank so that the seasoning is evenly distributed in the ketchup to achieve the desired taste and flavor.

4. Sterilization and disinfection

In order to ensure the food safety and shelf life of the ketchup, the production line will be sterilized at this stage. High-temperature sterilization technology is usually used to heat the ketchup liquid at a certain temperature to remove bacteria and microorganisms and extend the shelf life.Steps:

①High-temperature sterilization: The ketchup liquid passes through the sterilization equipment. Common sterilization methods include high-temperature instantaneous sterilization and high-temperature treatment of about 90℃ to 100℃ for several minutes. While ensuring the sterilization effect, the impact on the nutritional components and flavor of the ketchup is minimized.

②Cooling: After sterilization, the sterilized ketchup is quickly cooled by the cooling equipment to prevent the loss of ketchup flavor and quality degradation.

5. Packaging

The ketchup after sterilization and cooling enters the packaging stage. The packaging materials are generally plastic bottles, glass bottles or soft packaging bags, which can effectively maintain the freshness and hygiene of the ketchup. The packaging equipment on the production line includes automatic packaging machines, automatic filling machines, sealing machines and labeling machines.

Steps:

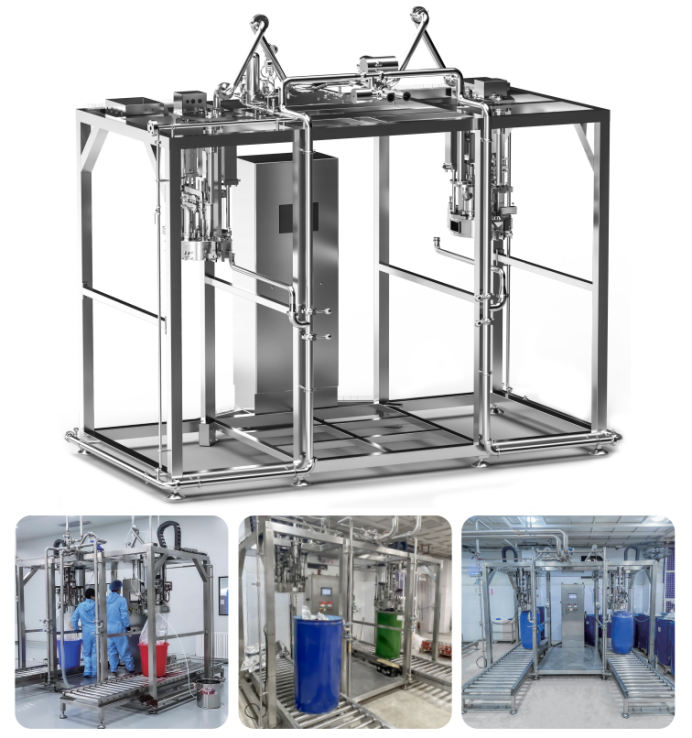

①Packaging: The ketchup is packed into bags by automatic packaging machines. There are large bag aseptic filling machines and small bag vertical packaging machines. You can also use bag-feeding packaging machines to pack ketchup into self-supporting bags.

②Filling: The ketchup is filled into bottles or cans, such as glass bottles, iron cans, plastic bottles, etc., by automatic filling equipment. The filling equipment will accurately fill according to the set capacity to ensure that the amount of ketchup in each bottle or can is accurate and consistent.

③Sealing: The bottles or cans filled with ketchup will be sealed by the sealing equipment to prevent the outside air from entering and ensure the freshness of the product.

④Labeling: Finally, the product label is attached to ensure that each bottle of ketchup has complete product information and production date, and then they are packed and prepared for shipment.

6. Finished product inspection and storage

At the last stage of ketchup production, the finished product will be inspected for quality. This includes checking the taste, color, texture and packaging integrity of the product to ensure that each bottle of ketchup meets food safety standards.

Steps:

①Quality inspection: Each batch of ketchup is subjected to sensory evaluation and laboratory testing to check whether it meets the standards.

②Storage and delivery: Qualified products can be placed in a cool, dry and ventilated warehouse, avoiding direct sunlight and high temperature and humidity, waiting for sales and transportation.

From the selection of raw materials, processing, seasoning, sterilization, packaging to final inspection, every link of the ketchup production line is crucial to the quality of the product. The modern production line equipment produced by Zhengzhou Hongle Machinery Equipment Co., Ltd. not only improves production efficiency, but also ensures the stability and safety of the product. Through these rigorous process flows, the ketchup produced can meet the high standards of taste, quality and hygiene of global consumers.