Improve egg quality and ensure food safety – fully automatic egg washing and processing production line

Improve egg quality and ensure food safety – fully automatic egg washing and processing production line

As consumers pay more and more attention to food safety and hygiene, how to ensure the sanitary quality of each egg has become an important challenge faced by egg producers. In particular, dirt, bacteria and other impurities often remain on the surface of eggs. How to clean eggs efficiently and hygienically has become a major problem in the development of the industry.

Solve the egg cleaning problem, we have the answer!

The fully automatic egg washing and processing production line that leads the industry trend, through advanced automation technology, not only greatly improves production efficiency, but also ensures the cleanliness and hygiene of each egg, so that your products stand out in the fierce market competition.

Why choose our egg washing and processing production line?

Efficient cleaning, saving labor costs Our egg washing production line adopts a fully automatic design, from egg collection, sorting to cleaning, drying and packaging, the whole process is intelligently operated, which greatly reduces labor costs. The cleaning capacity is as high as tens of thousands of eggs per hour, ensuring efficient production and helping enterprises to increase production capacity.

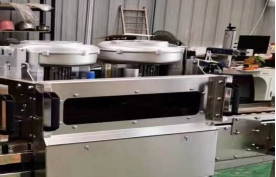

Automatic egg loading

Manual egg loading

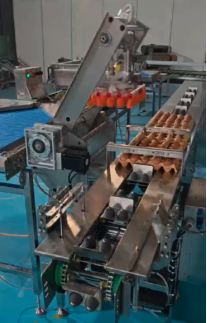

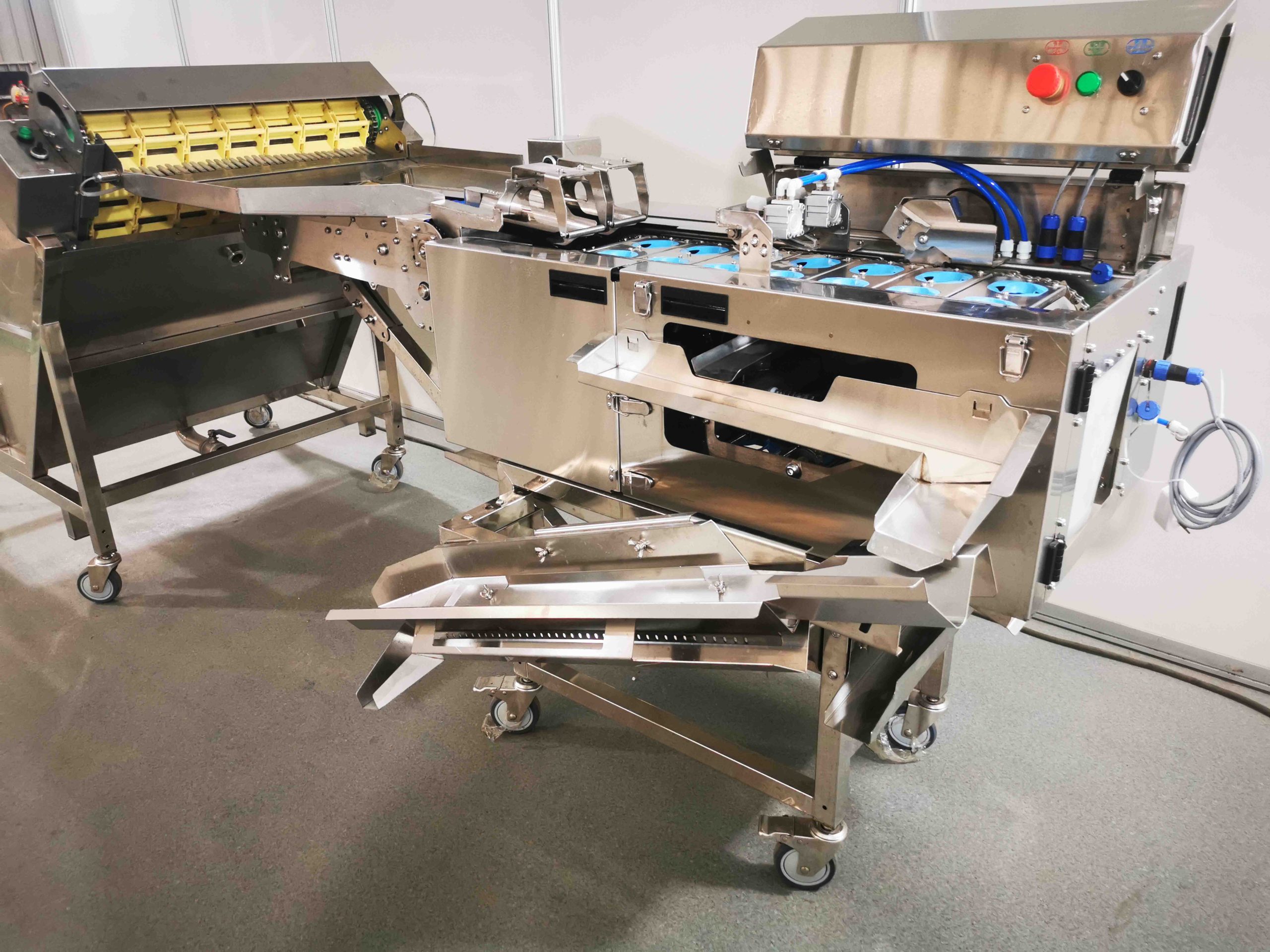

Automatic egg washing processing line

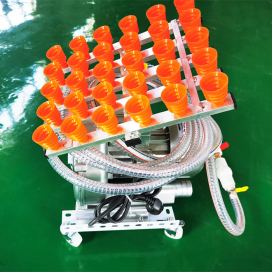

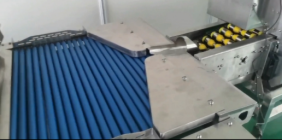

Gentle cleaning, perfect protection of eggshells Our cleaning system uses a combination of gentle scrubbing and intelligent spraying to effectively remove stains, dirt and bacteria on the surface of eggs, while ensuring that the eggshell on the surface of eggs is not damaged. Whether it is surface stains or stubborn pollution, they can be easily removed to ensure that every egg is clean as new.

Operation method: manually pour the whole basket (box) of chicken/duck eggs into the sink, the chicken/duck eggs are sent into the hair roller in an orderly manner under the action of the conveying roller, and the chicken/duck eggs are fully obtained under the action of the hair roller. Scrubbing, clean chicken/duck eggs are transported from the discharge end to pick out the bad eggs. Qualified eggs are transported to the conveyor belt, transported to the packaging machine or to the follow-up equipment as required for subsequent operations.

| 1 | 2 | 3 |

|

|

|

| egg pre-washing and loading machine | soft conveyor protect the eggs | Visual brush cleaning |

| 4 | 5 | 6 |

|

|

|

|

| air dryer | Light inspection | egg weight grading |

High standard hygiene to ensure food safety The cleaning production line is designed with strict food-grade hygiene to ensure that each link meets international hygiene standards. Automated operation minimizes manual contact to the greatest extent, avoids secondary pollution, ensures the safety and hygiene of eggs, and fully complies with the food safety regulations of various countries.

Environmental protection and energy saving, reduce operating costs The egg cleaning and processing production line adopts an efficient and energy-saving design to effectively save water and electricity consumption. While ensuring efficient cleaning, it also reduces operating costs. Materials and processes that meet environmental protection standards ensure that the equipment can still operate stably under long-term use.

Widely applicable to enhance your competitiveness Whether it is a large egg processing enterprise or a small and medium-sized farm, the fully automatic egg cleaning and processing production line can provide the best solution. Our equipment can adapt to production needs of all sizes, helping companies increase production, reduce costs, and improve product quality, thereby gaining an advantage in the fiercely competitive market.

Successful Cases

Since a large egg processing plant introduced our egg washing production line, its production efficiency has increased by 40%, the quality of eggs has been significantly improved, and its market share has also increased significantly. The person in charge of the company said: “The automated washing line not only greatly reduced our labor costs, but also effectively improved our production efficiency and egg quality, becoming a powerful driving force for our development.”

Choose us and be at the forefront of the industry

As consumers’ requirements for food quality and hygiene continue to increase, the fully automatic egg washing and processing production line will provide strong support for your company. Whether it is to improve production efficiency, reduce production costs, or improve the market competitiveness of products, we can provide you with professional solutions.

Contact us now to learn more about the egg washing production line!

Now, by purchasing our egg washing production line, you can not only enjoy the advantages of an efficient washing system, but also get free equipment installation and technical training services, making your production smoother, more efficient and safer. Conclusion

Through this automated and intelligent cleaning and processing method, your eggs will stand out in the market and win the trust of consumers. The fully automatic egg washing and processing production line not only improves production efficiency, but also ensures food safety. It is your best choice to improve product quality and enhance market competitiveness.