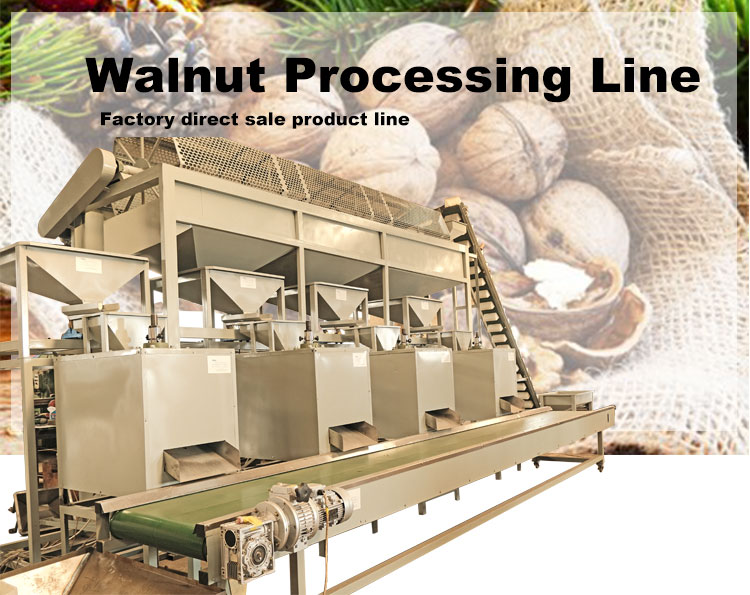

The walnut screening, shelling and grading production line is an efficient and automated walnut processing production line designed for large-scale walnut processing. It can realize the integrated operation of walnut screening, shelling, grading and separation. The production line can process 1,000 to 1,500 kg of shelled walnuts per hour and is suitable for food processing companies, nut processing plants and agricultural cooperatives.

Feeding system: Automatic feeding device, which evenly feeds shelled walnuts into the production line to ensure continuous and efficient production.

Screening system: Walnuts are graded by size through vibrating screen or drum screen to facilitate subsequent shelling.

Shelling system: Mechanical extrusion or impact shelling machine is used to efficiently remove walnut shells while protecting the integrity of the kernels.

Separation system: Walnut kernels are separated from shells, debris, etc. by air flow sorting, vibrating screen or specific gravity separation technology.

Grading system: Walnut kernels are graded according to their size and integrity to meet different market needs.

Dust removal system: Equipped with dust removal equipment to reduce dust pollution during the production process and improve the working environment.

Control system: Automated control system to achieve intelligent operation and monitoring of the entire production line.

| NO./ITEM NAME | SPECIFICATION |

| 1.Elevator | Size:0.6*0.6*5m Power:1.1kw |

| 2.drum sieve classifier (Drum grading avoids sieve holes,Separate size 4 levels) | Size: 5.5*1.1*2.5M Capacity:1000kg/h |

| 3.Frame | Classifier, supporting chassis heightening, matching the height of the hopper shelling machine |

| 4.Electromagnetic quantitative feeding hopper | Size: 1*1*1.6 meters to match the production line, enter three shelling machines respectively 0.050kw |

| 5.Walnut Sheller | Size:3.5*0.9*1.3m power:3kw |

| 6.Centrifugal shell opener for walnut stuck fruit | 3.5*0.9*1.3M Power:1.5kw |

| 7.Elevator | power:0.75kw voltage 380v 50hz |

| 8.conveyor pick belt Rollup Delivery | Size :6*0.6*1.5 Material :pvc belt、Frame carbon steel, gusset stainless steel |

| 9.Elevator (Lift to vibrating screen) | power:0.75kw voltage: 380v 50hz |

| 10.Special grading sieve for walnut | Size :3*1.2*1.2 Material: Screen stainless steel, frame carbon steel |

| 11.Crushed Kernel Shackron | Power 1.5kw Material: carbon steel q235 |

| 12.Electromagnetic quantitative feeding hopper | size:1.5*1*1.6M 0.050kw |

| 13.Pvc elevator | Power:0.75kw |

| 14.Double fan shell kernel separator (positive pressure) | 4.4kw For separating halves and shells |

| 15.Conveyor pick belt Pick out defective nuts | Size: 6*0.6*1.5 Material: pvc belt, frame carbon steel, gusset stainless steel |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.